Outdated safety processes in food & drink manufacturing

In food and drink manufacturing, health and safety can’t be left to chance. From slips and trips to chemical safety and contractor risks, the stakes are high — and regulations are strict. Yet many businesses still rely on outdated methods such as paper records, spreadsheets, or siloed systems.

These processes make compliance harder, reduce visibility, and lead to disengaged employees. To build a proactive safety culture, manufacturers must embrace modern, digital solutions.

Why manual and siloed safety systems fail

Paper-based safety processes are inefficient

Paper risk assessments and incident logs are easy to misplace, slow to update, and difficult to share. In fast-paced environments, these delays can lead to missed hazards and compliance gaps.

Siloed health & safety systems create blind spots

Some organisations move away from paper only to adopt multiple unconnected systems. Without integration, managers struggle to get a complete view of compliance, making audits stressful and reactive.

Low staff engagement with complicated systems

If reporting a hazard or incident is too complicated, employees won’t do it. Poor user experience results in under-reporting and unmanaged risks.

Traditional safety approaches are reactive

Old processes focus on ticking boxes rather than preventing accidents. Without real-time insights, managers can’t easily spot patterns or address root causes before incidents escalate.

How digital health & safety software solves these challenges

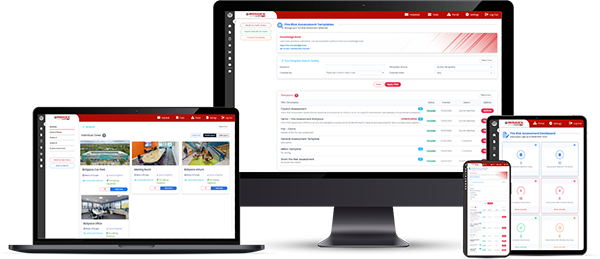

AssessNET empowers food and drink manufacturers to stay compliant, reduce incidents, and build a proactive safety culture — all in one cloud-based, mobile-friendly system.

Digital risk assessments improve visibility

Instead of manually filing paper forms after each shift, managers can log hazards instantly. For example, if a conveyor belt guard is missing, the production supervisor can record it on-site via mobile, assign the fix to maintenance, and track completion, all within AssessNET. This ensures risks are actively managed, not forgotten in a filing cabinet.

Accident & incident management speeds response

Slips on wet floors and minor machinery injuries are common in food production. With AssessNET, staff can report incidents straight from the shop floor. Managers then investigate root causes (for example: inadequate floor mats or poor signage) and assign corrective actions. Over time, patterns emerge, helping prevent repeat accidents.

CoSHH & SDS management simplifies chemical safety

Cleaning agents and disinfectants are essential in food environments but pose risks if mismanaged. With AssessNET staff can scan a QR code on the cleaning station can instantly access handling instructions, reducing the chance of misuse and ensuring compliance with HSE requirements.

Contractor management strengthens compliance

When external engineers arrive to service refrigeration units or install new machinery, it’s vital they meet site safety and hygiene standards. AssessNET digitises inductions, stores insurance and certification records, and ensures contractors are approved before work begins, reducing risks from third-party activity.

Training management & eLearning builds competence

Staff turnover in food and drink manufacturing can be high, making training critical. AssessNET allows HR or safety managers to track who has completed hygiene training, who needs a refresher on machinery operation, and automatically schedule reminders.

Permit to work controls high-risk tasks

High-risk maintenance tasks such as welding during equipment repairs or cleaning inside confined storage tanks, require strict control. With AssessNET, permits are created digitally, conditions are outlined clearly, and authorisations are tracked in real time. This ensures only qualified personnel complete dangerous tasks, protecting both workers and operations.

The future of food & drink manufacturing safety

Traditional paper-based or siloed safety systems can no longer keep pace with the sector’s demands. By adopting a digital platform, manufacturers can improve efficiency, ensure compliance, and engage their workforce in building a safer future.

Book a 30-minute demo to find out how AssessNET can support your health and safety strategy.

Frequently Asked Questions (FAQs)

What are the biggest health and safety risks in food and drink manufacturing?

Common risks include slips and trips, chemical exposure, unsafe machinery use, contractor activities, and inadequate staff training.

Why are paper-based health and safety processes ineffective?

Paper processes are time-consuming, prone to errors, and difficult to track across multiple sites, making compliance harder to manage.

How does digital health and safety software help compliance?

Platforms like AssessNET centralise risk assessments, incident reporting, training, and contractor management, giving full visibility and audit readiness.

Can digital systems improve staff engagement in safety?

Yes. User-friendly, mobile-enabled systems make it easier for staff to report hazards and incidents, encouraging participation and building a safety culture.

What modules are most useful for food and drink manufacturers?

Key modules include risk assessments, CoSHH & SDS management, accident & incident management, contractor management, training & eLearning, and permit to work.